Everything about "Unveiling the Science Behind Demulsifiers: A Closer Look at Emulsion Breaking"

Water contamination is a notable worry in several industrial procedures, such as oil refining, chemical production, and wastewater therapy. Maximum horsepower oil count on water for various purposes, including cooling, cleaning, and as a component of their ultimate products. Having said that, the presence of contaminants in water may lead to functional problems and negatively influence item top quality.

One successful service to deal with water poisoning complications in industrial procedures is the use of demulsifiers. Demulsifiers are chemical substance representatives that aid separate water coming from oil or various other hydrocarbons. They function by destabilizing the cream created when water and oil mix with each other, permitting for simpler splitting up.

Industrial processes typically entail the use of sizable volumes of water that happen in to call with oils or hydrocarbons. This connect with may happen due to leakages or spills throughout manufacturing or transit, leading to the accumulation of solutions. Emulsions are stable mixtures where very small droplets of one liquid are scattered within yet another fluid.

Solutions present a number of difficulty in commercial processes. First, they raise the thickness of fluids, which can easily impede fluid circulation through pipelines and equipment. This raised viscosity may lead to decreased performance and efficiency as even more electricity is required for pumping fluids.

The second thing is, creams can induce fouling and obstructions in heat exchangers and other method devices. The deposition of solution beads on surfaces lowers warmth transmission productivity and limits circulation flows. This fouling not just decreases working productivity but also enhances upkeep expense as a result of to frequent closures for cleaning.

In addition, solutions may adversely affect item premium in business such as oil refining or chemical manufacturing. For instance, the presence of water in unpolished oil in the course of refining may lead to deterioration issues and lessen the premium of refined products like gas or diesel fuel.

Demulsifiers play a essential duty in addressing these obstacle by cracking down creams into their corresponding elements - water and hydrocarbons - making it possible for for easier splitting up and subsequent therapy. They accomplish this by adsorbing onto the solution droplets, interfering with the interfacial strain between water and oil.

Demulsifiers may be classified right into various styles based on their chemical structure and method of action. Some common styles include surfactant demulsifiers, linking demulsifiers, and electrostatic demulsifiers.

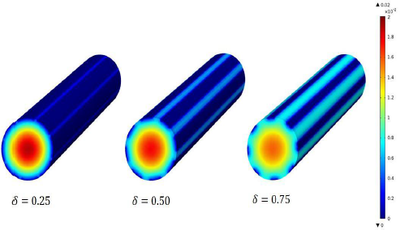

Surfactant demulsifiers are the very most extensively utilized kind and job by minimizing the interfacial tension between water and oil. They contain molecules with both hydrophilic (water-attracting) and lipophilic (oil-attracting) homes. These particles migrate to the oil-water user interface, forming a steady film that deteriorates the emulsion's stability.

Coalescing demulsifiers work through promoting droplet accident and combination within the solution. They typically possess a much higher molecular body weight than surfactant demulsifiers, which permits them to unite multiple droplets with each other. This link activity assists in the merging of smaller sized beads into larger ones that are simpler to separate.

Electrostatic demulsifiers use an electricity industry to destabilize cream droplets. Through using an electricity cost to either water or oil period, these demulsifiers generate pugnacious or appealing forces between droplets, resulting in them to agglomerate or clear up a lot more rapidly.

The option of an necessary demulsifier depends on various elements such as solution characteristics, process ailments, and intended separation productivity. Industrial drivers need to take into consideration factors such as temp, pH degrees, salinity, and attention of contaminants when deciding on a suited demulsifier for their details app.

Once included to the system, demulsifiers facilitate effective separation of water from oil or hydrocarbons by means of processes like gravitational force working out or centrifugation. Separated water can after that go through more treatment just before being discharged or reused in commercial processes.

In verdict, water contaminants is a considerable problem in commercial methods that rely on water for a variety of purposes. Solutions formed when water and oil mix together may lead to functional obstacle, decreased performance, and item premium issues. Demulsifiers play a crucial duty in cracking down these emulsions, allowing for simpler splitting up of water from oil or hydrocarbons. Their collection and application depend on numerous aspects specific to each industrial method. By effectively taking care of water contaminants problems, demulsifiers contribute to improved functional efficiency and product top quality in commercial procedures.